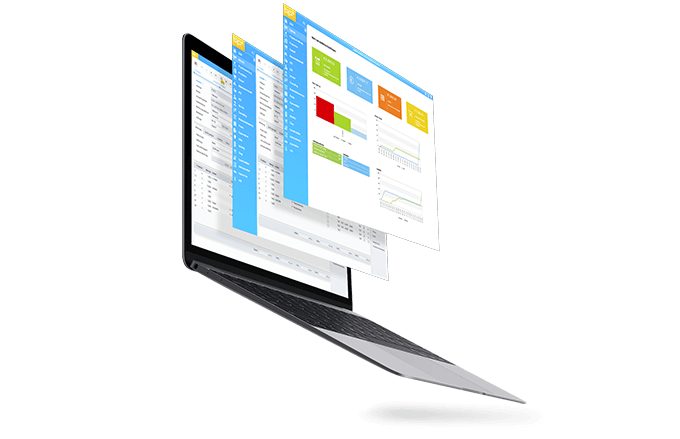

Put an end to isolated applications - APplus meets your personal requirements profile and covers all relevant areas in an integrated way for you.

Do you manufacture machines and provide service for them, but at the same time also deal in other products and spare parts? Or do you combine series and individual production? We offer you an ERP solution that covers even the most diverse requirements in an integrated manner.

This way you consolidate your isolated applications and benefit from seamless data flows. For efficient coverage of your entire business processes - from project planning to manufacturing to service.

ERP highlights for hybrid manufacturers

Integrated project module

For better and more efficient planning of your resources.

Powerful detailed planning

The best for your production.

Smart service

Design your service intelligently with Predictive Maintenance.

Bestandteile der ERP-Lösung für die hybride Fertigung

- PLM / CAD integration

- Order-related individual production

- Product configuration / assemble-to-order production

- Growing BOMs

- Project Development

- Advanced Planning & Scheduling

- Container management

- Consignment warehouse

- Expectation of credit

- Automatic connection to the ATL@S procedure

- Project and product costing

- Mobile use

- CRM (incl. 360-degree view of your customers)

- After-sales customer care

- Service with integrated helpdesk

Simple (and) convincing –

with functionality and flexibility

Project-based manufacturing

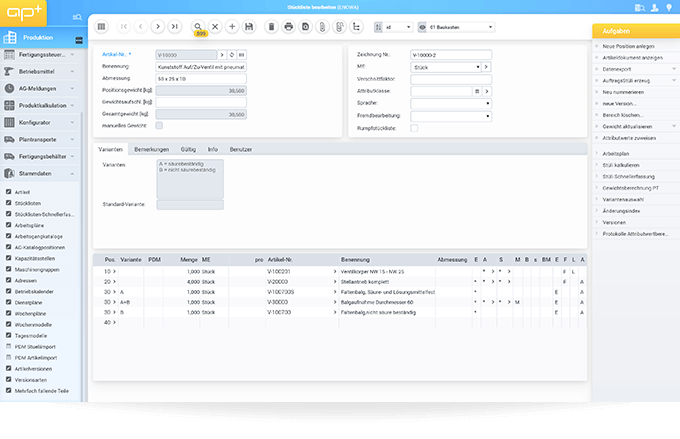

With our project module, we offer you an efficient way to centrally plan and process projects and customised orders. Even in the quotation phase, orders can be managed like projects - because in APplus the business and production views are linked.

Created calculations can be easily converted into the corresponding view for production. Based on the EDM/PDM interface, you are also able to automatically transfer growing parts lists to the other process stages. Our ERP solution thus ensures maximum efficiency in your project business.

Plan production processes graphically

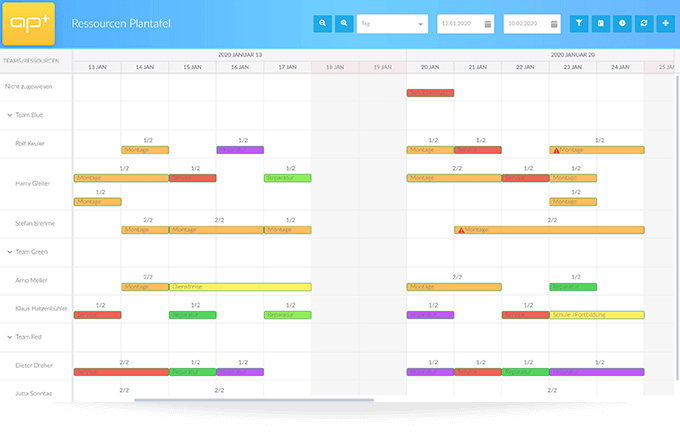

APplus detailed planning enables the complete management of your supply chain - in the form of an integrated tool. For this purpose, the module provides you with a wide range of functions with which you can plan your production automatically. Necessary follow-up processes such as scheduling or the generation of order proposals are also carried out without additional manual effort.

The graphical planning board (Gantt chart) clearly prepares the information necessary for the orders as well as the individual work steps for you. Accordingly, overdue actions or deadlines can also be determined and graphically displayed within the framework of forward scheduling. Through the efficient visual planning of your production processes, you are able to shorten throughput times and significantly increase your adherence to delivery dates.

Smart service for maximum satisfaction

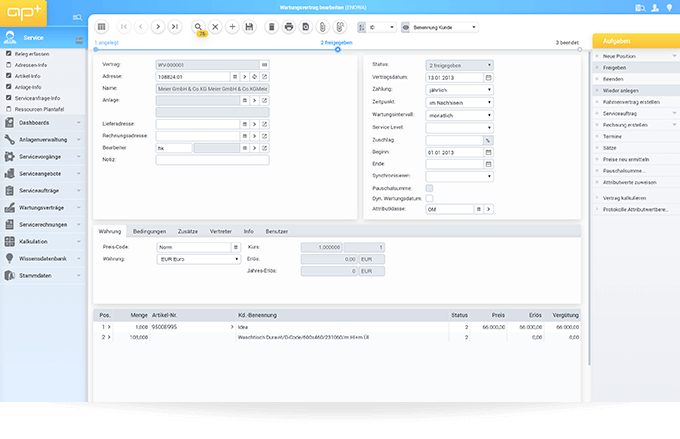

APplus unterstützt Ihre Service-Prozesse mit modernster intelligenter Technik – in Form unseres innovativen APplus-Service Modul. Durch Anbindung Ihrer Maschinen an die Cloud wird es möglich, Betriebsdaten kontinuierlich zu analysieren und so potenzielle Stillstände bereits präventiv vorauszusagen. Dadurch sind Ihre Techniker in der Lage, rechtzeitig einzugreifen, bevor es zum Produktionsausfall kommt.

Bei der Planung eines Wartungstermins greift APplus-Service auf den umfassenden ERP-Datenpool zurück, um benötigte Eigenschaften wie Zertifizierungen in die Personalplanung mit einfließen zu lassen. Vor Ort erhält der zuständige Techniker alle relevanten Informationen automatisiert an sein mobiles Endgerät gesendet, auf dem er auch seine Einsatzzeiten bucht sowie den Wartungstermin dokumentiert. Alle erfassten Informationen werden automatisiert an APplus zurückübertragen.

Efficient maintenance

Our service module offers you an efficient way to plan, control and document your maintenance processes. At the centre of the module is the system and device management. There, it is documented which components are used by customers and in which condition they are.

With the help of the service orders, all pending tasks can be processed quickly and efficiently. This includes, among other things, the allocation of a machine in APplus, classic processes of maintenance and travel time accounting as well as extensive support for spare parts procurement. In addition, maintenance contracts with any duration and due date can be conveniently created and mapped in our ERP system.