ERP solution for mechanical and plant engineering

In mechanical and plant engineering, it is essential that all departments have a standardised overview of ongoing and completed projects. In addition to CRM and shared project management, APplus also offers PLM and CAD integration. You also receive a centralised overview of your internal resource planning. All information is also available to your service department so that they can ensure the continued support of your customers.

On this page we give you an overview of why APplus is perfectly tailored to the requirements of your company.

This is how APplus supports the

Mechanical and plant engineering:

PLM/CAD integration

Your direct access to development and production data.

Growing BOMs

As flexible as the final order. Successively expand your BOMs on the fly.

Project

administration

All important information at your fingertips with just one click.

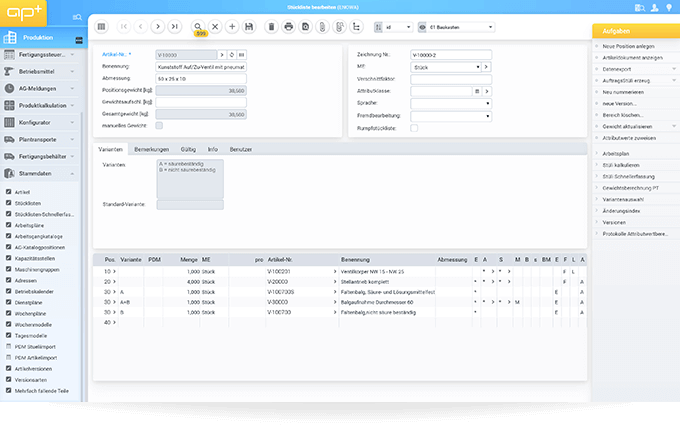

PLM / CAD integration

PLM integration enables homogeneous access to development and production data. After being released, BOMs created in the CAD system are immediately available in production. The cross-department process is ensured.

The Web service architecture of APplus pays off particularly in these areas. APplus gives design engineers and production scheduling employees access to information that is up-to-date and consistent for everyone involved—even though each department operates solely with its own legacy system: Design engineers use CAD and the integrated EDM/PDM system, and the employees in scheduling or procurement use the PPC module from APplus.

Growing BOMs

Often when an order is submitted or accepted, the particulars of how the production article in question is built still have not been specified. However, production has to begin even before all product data is at hand and the BOMs have been resolved down to the lowest level. APplus enables you to establish an expanding BOM that you can successively expand by adding all customer data in order to design the article.

Project Management

As part of project planning, APplus supports all planning work processes ranging from the quotation phase to the complete commissioning of the control system or machine.

Calculation

The extensive costing functions provided by APplus are of great importance for optimizing the production process and for business success. Detailed, production-oriented preliminary costing, concurrent costing and final costing, including detailed variance analyses, meet all requirements.

Contract manufacturers in particular value the options for assigning all costs directly to the pegged order: Stock material, in-house production, external production and even all order-related procurement transactions including all additional costs to be charged. Repetitive manufacturers are usually more likely to use standard cost accounting, which APplus offers as an alternative.

Maßgeschneiderte Lösung für

den Maschinenbau & Anlagenbau

Entdecken Sie die Vielseitigkeit unserer ERP-Software, speziell angepasst für die Anforderungen im Maschinenbau.