Our means for high efficiency in your production and best possible product quality? The ERP solution for medical technology: APplus.

Traceability and transparency - in a highly sensitive area such as medical technology, the utmost care and accuracy are essential.

Mit APplus erhalten Sie ein umfangreiches und verlässliches Werkzeug, um den hohen Ansprüchen an Fertigungsqualität und Lieferfähigkeit gerecht zu werden.

ERP highlights for medical technology

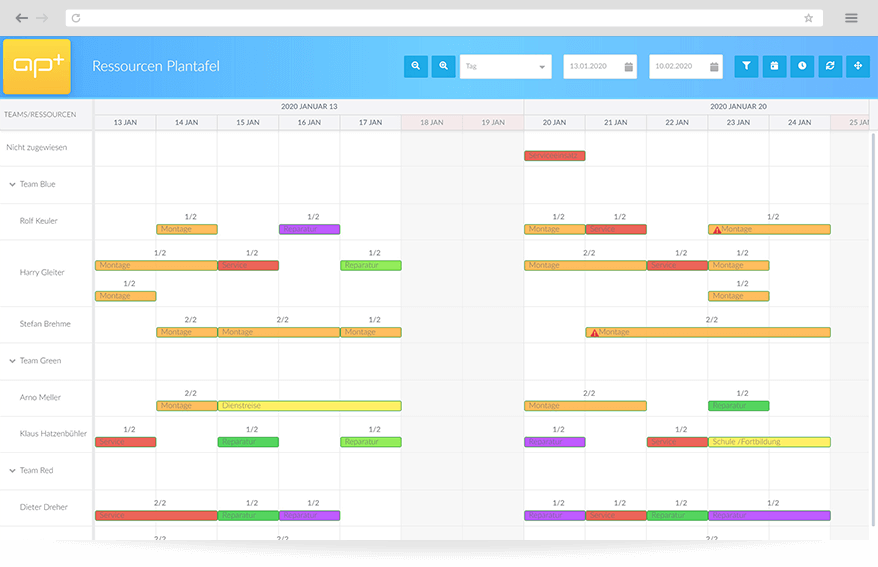

Powerful detailed planning

Discover your new powerful and holistic planning tool now.

Complete traceability

Transparency and traceability are the cornerstones of APplus.

Stand-dividing features

Use the individually configurable stock separating features.

Bestandteile der ERP-Lösung für die Medizintechnik

- Advanced Planning & Scheduling

- Capacity planning

- Contextual replanning

- Complete traceability of batches

- Configurable stock separating features

- Product lifecycle and quality management

Simple (and) convincing –

with functionality and flexibility

Flexible storage allocation

With the help of the configurable stock-separating characteristics, you have the option of including your own freely definable criteria in the stock allocation in addition to information such as serial or batch numbers.

This allows scenarios to be mapped in practice in which goods have to be removed, for example, according to the order in which they are received or on the basis of a best-before date.

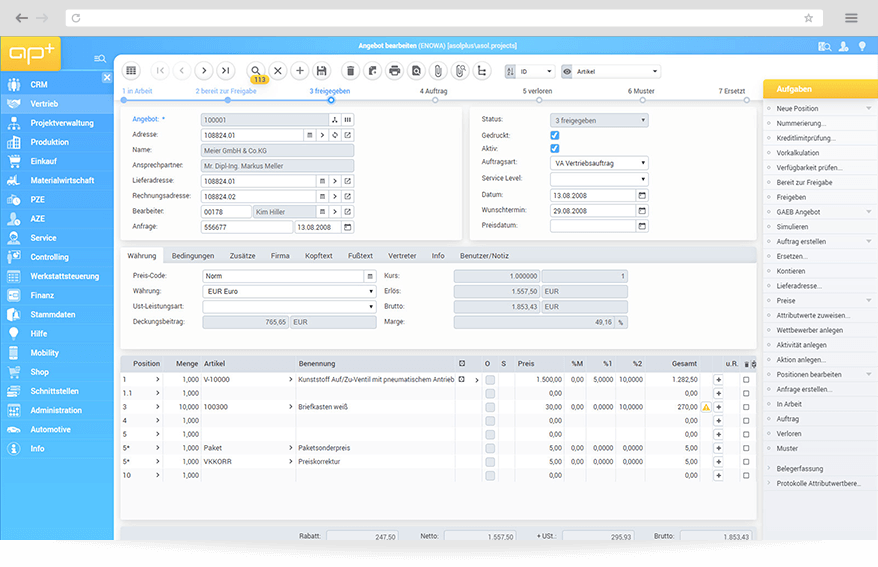

Powerful planning

With APplus Detailed Scheduling, you get a powerful, holistic planning tool to manage your entire supply chain. Our solution offers you a comprehensive range of user-friendly tools for the automated planning of your production.

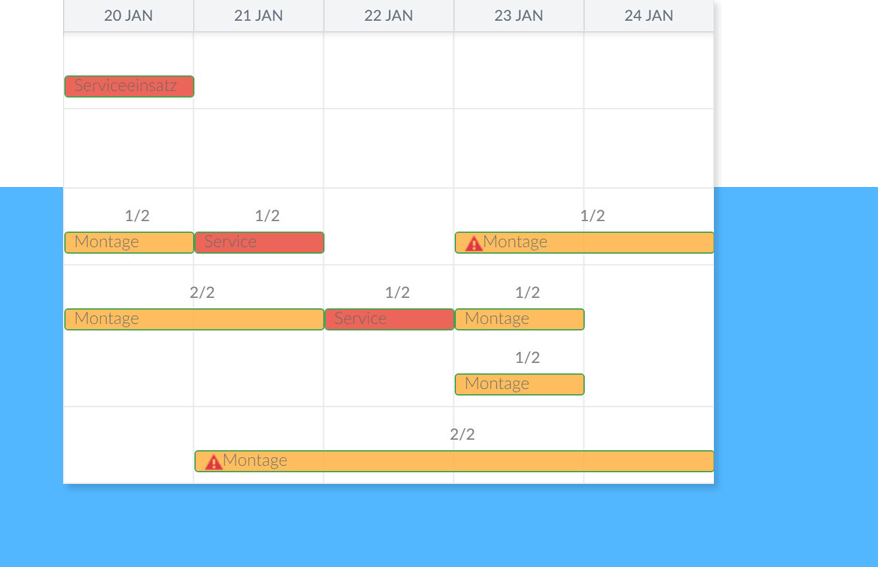

Any subsequent steps, such as scheduling or the generation of order proposals, also run automatically if desired. Information on orders and operations is visually presented as a planning board (Gantt chart).

In this way, overdue work steps and deadlines can be identified and graphically displayed via forward scheduling. Through the optimised coordination of all production processes, throughput times can be accelerated and on-time delivery increases.

Complete transparency

Delivered and installed batch and serial numbers can be frozen and seamlessly tracked at any time. For maximum security in a highly sensitive industry.

Highest quality

With the help of integrated product lifecycle and quality management, we offer you the tools for the highest quality demands in your medical products.