ERP solution for equipment and apparatus engineering

Make your project a success.

With APplus, we offer you a specialised solution that is optimally designed for the requirements of equipment and apparatus engineering. It supports you in managing and controlling your entire business process in an integrated manner. In this way, you reduce your costs and expand your competitive advantage.

As an ERP specialist for SMEs, we support you with the accumulated experience from over 1,700 customer projects.

ERP highlights for equipment and apparatus manufacturers

PLM/CAD integration

Homogeneous access to development and production data.

Product configurator

Alternative items in BOMs or work plans, simple formulas for variations in quantity or size

Growing BOMs

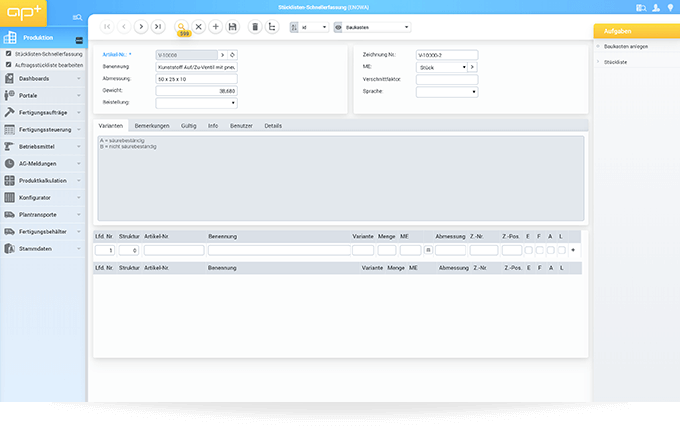

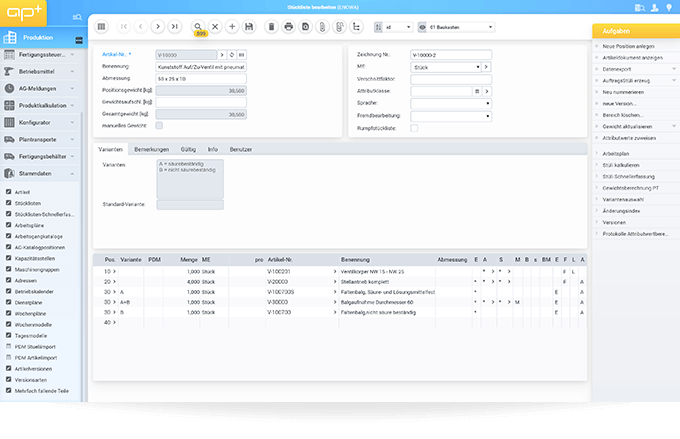

As flexible as the final order. Successively expand your BOMs on the fly.

Bestandteile der ERP-Lösung für den Geräte- und Apparatebau

- PLM/CAD integration

- Order-related individual production

- Product configuration / assemble-to-order production

- Growing BOMs

- Project Development

- Project and product costing

- Support for returns

- In-house service processing

Seamless cooperation -

in all areas

Integrated solution for your success

With our integrated industry solution, you seamlessly cover all stages of your business process: from planning and sales to production and service. In doing so, APplus supports production models for both make-to-order and project manufacturing as well as for make-to-stock production. In this way, the vertical integration of manufacturing into the rest of the production environment is promoted.

Our ERP module helps you optimise your processes in the extended enterprise, accelerate innovations and minimise production lead times. Customer service also benefits: With our comprehensive function portfolio, you can always be sure to develop and market the right products economically.

PLM/CAD integration

Through PLM integration, APplus ensures a seamless connection between ERP on the one hand and development and production data on the other. Parts lists created in the CAD system can be used immediately in production after approval. In this way, cross-departmental collaboration is ensured seamlessly at all times.

In this context, you also benefit particularly from the web service architecture. Thanks to APplus, both designers and AV employees can work in their traditional system: The designer with the CAD as well as the integrated EDM/PDM system, the AV or procurement employee with the PPS module. At the same time, both are able to access all relevant data.

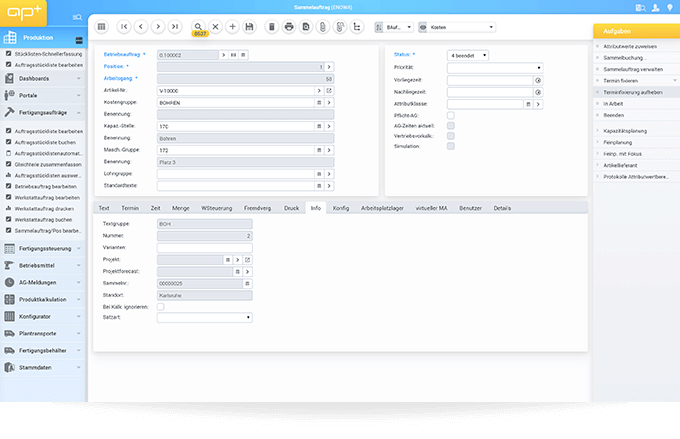

Order-related individual production

Even order-related individual production is no problem with APplus. Our solution enables you to optimally plan and utilise your production and personnel capacities.

Product configuration / assemble-to-order production

Decision tables are also available at any time if required. The characteristics list (according to DIN 4000) can be used as a central rationalisation tool in variant production. It can be used to quickly and easily find suitable parts in development - and thus efficiently reduce the variety of parts.

Growing BOMs

What exactly is the composition of an article to be produced? Often this question is not fully clarified at the beginning of the design process. So that you can nevertheless start production as quickly as possible, APplus supports you with the function of the growing parts list. This can be gradually resolved in the course of the process, while complete parts and components are already being manufactured.

Project Development

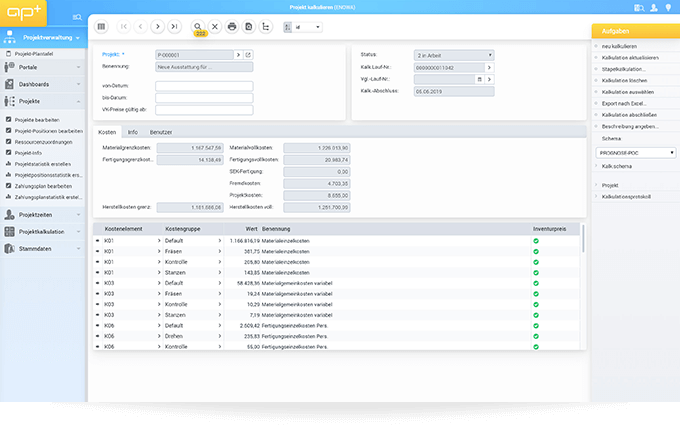

Project and product costing

If you want to operate efficiently, you have to calculate efficiently. APplus supports you here with comprehensive costing functions. Whether detailed, production-related preliminary costing, concurrent or final costing, including variance analyses - with APplus you always have an overview of your costs and expenses.

Especially for contract manufacturing, costs can be assigned directly to the order that caused them: From stock material to in-house production to external production and all order-related procurement processes including all relevant additional costs. Serial production, on the other hand, benefits from standard cost accounting, which can also be carried out easily and efficiently in APplus.