Optimise project planning, improve service, increase productivity.

APplus is a comprehensive industry solution precisely tailored to the requirements in vehicle construction. APplus enables you to integrate and control all of your company processes, enabling you to expand your competitive advantages and significantly reduce costs. APplus is based on the experiences we have gained in our many years of collaborating with over 1,400 customers.

From manufacturing to management, from product sales to service, all components of our industry solution work together seamlessly. They support production models for make-to-order, make-to-stock and project-related production while promoting the vertical integration of the production area with the rest of the production environment.

So unterstützt APplus

den Fahrzeugbau

From manufacturing to management, from product sales to service, all components of our industry solution work together seamlessly. They support production models for make-to-order, make-to-stock and project-related production and service while promoting the vertical integration of the production area with the rest of the production environment.

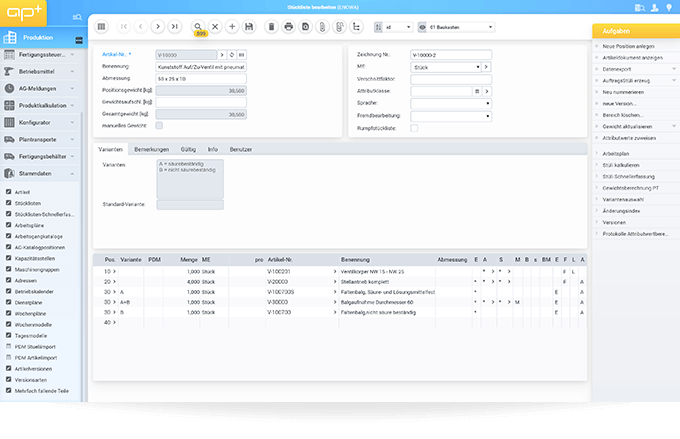

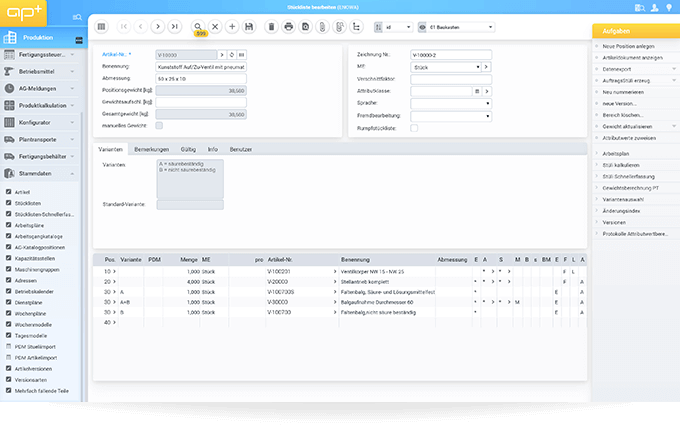

PLM/CAD integration

Your direct access to development and production data.

Growing BOMs

As flexible as the final order. Successively expand your BOMs on the fly.

Project

administration

Jederzeit alle wichtigen Informationen mit nur einem Klick zur Hand.

Calculation

Production-orientated calculations for all requirements.

Bestandteile der ERP-Lösung für den Fahrzeugbau

- Forecast calculation

- Product Configurator

- Payment plans

- Sales bills of materials

- Leasing module

- Traceable at all times

- Service and warranty module

- Project and product costing

- CRM (incl. 360-degree view of your customers)

- After-sales customer care

- Service with integrated helpdesk

ApPlus für den Fahrzeugbau –

Darauf

fährt die Branche ab

PLM / CAD integration

PLM integration enables homogeneous access to development and production data. After being released, BOMs created in the CAD system are immediately available in production. The cross-department process is ensured.

The Web service architecture of APplus pays off particularly in these areas. APplus gives design engineers and production scheduling employees access to information that is up-to-date and consistent for everyone involved—even though each department operates solely with its own legacy system: Design engineers use CAD and the integrated EDM/PDM system, and the employees in scheduling or procurement use the PPC module from APplus.

Growing BOMs

Often when an order is submitted or accepted, the particulars of how the production article in question is built still have not been specified. However, production has to begin even before all product data is at hand and the BOMs have been resolved down to the lowest level. APplus enables you to establish an expanding BOM that you can successively expand by adding all customer data in order to design the article.

Project Management

Die APplus-Software für den Fahrzeugbau unterstützt im Rahmen der Projektierung alle planenden Arbeitsvorgänge von der Angebotsphase bis hin zur vollständigen Inbetriebnahme.