ERP system for toolmaking

The tool for your project success.

Everything you need for your project business: economical one-off production and efficient service. APplus is your tool for success!

We know your challenges: Realising order-related individual projects - and remaining economical at the same time. No easy discipline, but with our ERP software for toolmaking this is no problem.

With the help of our powerful project module, you can plan your orders from the initial idea to production - including comprehensive costing options and support for growing parts lists. APplus also makes your service area smart, for integrated maintenance processes and optimal customer satisfaction.

ERP-Highlights für den Werkzeugbau

integrated project management

From planning to implementation.

Growing BOMs

Flexible order creation at any time.

Smarter Service

Offer your customers more through intelligent maintenance.

Projektverwaltung im Werkzeugbau

Our project management enables you to centrally plan and control all project-related processes and data. Orders are managed and processed like projects as early as the quotation and planning phase.

This means that the business calculation can easily be transferred to the corresponding manufacturing view for production if required. With the help of the EDM or PDM interface, growing parts lists can also be transferred to the subsequent process stages without manual effort - for consistently efficient order processing in your projects.

Flexible Planung, anpassbare Stücklisten

Changes are often made to the detailed structure of the tools after the quotation phase. For example, product-related parts lists sometimes have to be adapted and expanded afterwards.

However, this is no problem with our ERP software for toolmaking. We offer you the possibility to work with growing parts lists. Additional data can thus be successively entered to finalise the design plans.

Machen Sie Ihren Service smart

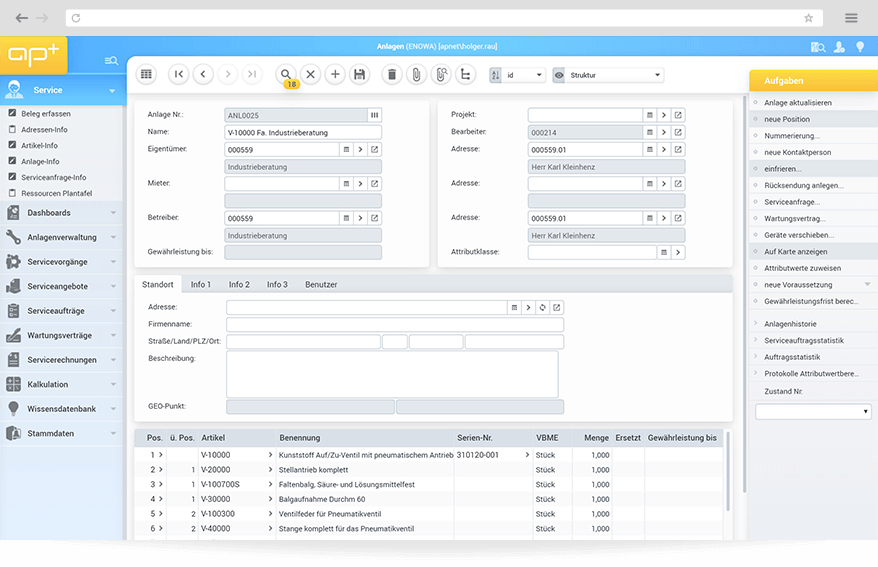

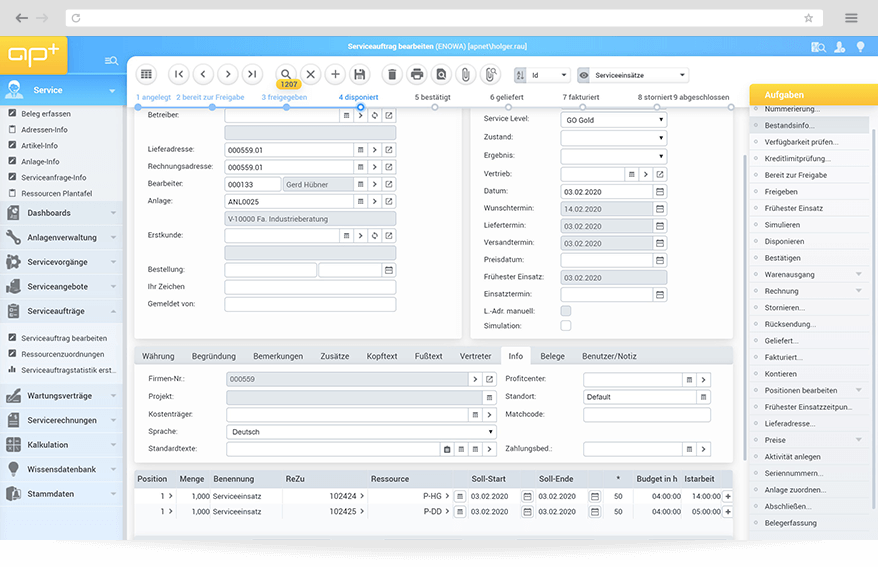

APplus provides you with a powerful tool for planning, controlling and documenting your service processes. The core of the service function area is a system and device management that documents exactly which components are installed at the customer's site and in which condition.

All relevant tasks can be completed quickly and easily in service orders. All requirements, from standard functions such as the allocation of a tool in APplus to typical tasks of a mechanic and travel time accounting to the procurement of spare parts, can be mapped. Of course, maintenance contracts can also be agreed in APplus within the framework of any terms and due dates.

APplus ermöglicht Ihnen die optimale Planung und Auslastung Ihrer Fertigungs- und Personalkapazitäten.

Weitere Funktionen für den Werkzeugbau

- PLM / CAD integration

- Order-related individual production

- Growing BOMs

- Project Development

- Project and product costing

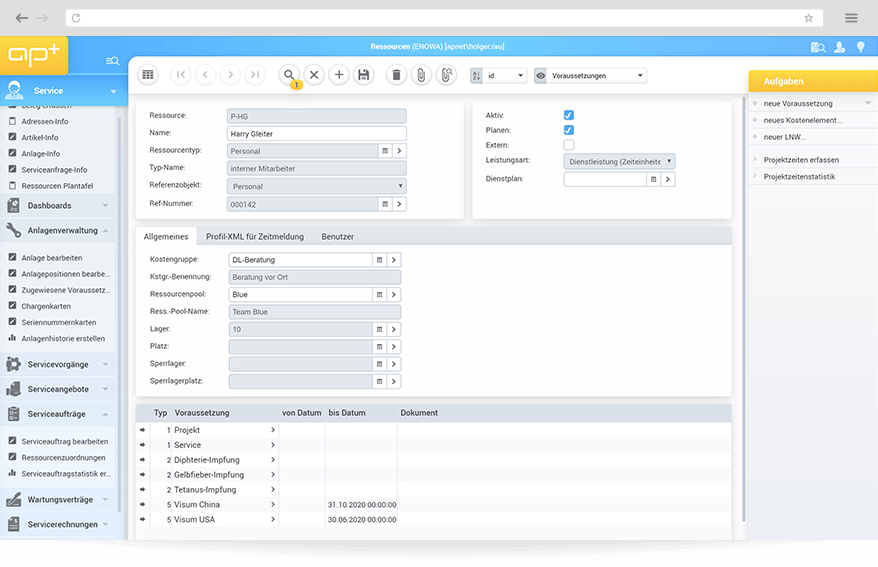

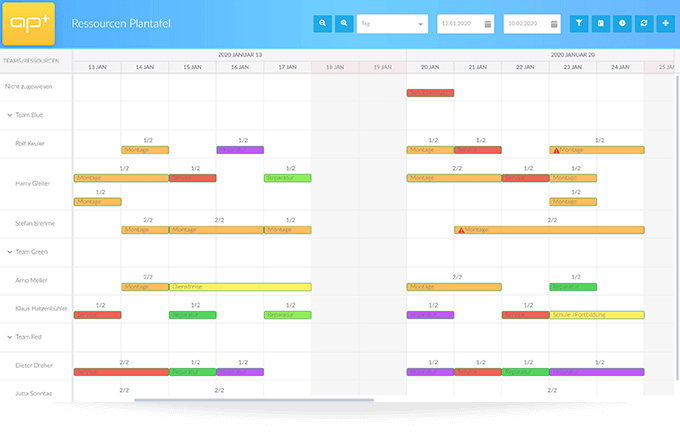

- Resource planning

Projektkosten im Blick dank APplus

A central factor for the profitability of a project is a comprehensive calculation. Here, our ERP solution supports you with a broad functional portfolio that is optimally tailored to your requirements.

Whether preliminary, final or ongoing costing including detailed variance analyses - APplus provides you with an up-to-date overview of planned and actual cost expenditure at all times.

Effiziente Planung und Terminierung

APplus already supports you in the offer phase with project-related effort and resource planning. This allows you to start with the rough planning of deadlines, personnel and costs at the earliest possible stage.

The production processes are scheduled in the graphic planning board: it presents all results in a clear and modern display. Any fine corrections such as postponements can be made directly in the planning board.

Maßgeschneiderte Lösung für

den Werkzeugbau

Entdecken Sie die Vielseitigkeit unserer ERP-Software, speziell konzipiert für die Anforderungen im Werkzeugbau.