Adquisición de datos de producción APplus

Whether logging orders or tracking staff work time-optimized and secure plant data collection from APplus means all your company processes run smoothly. Whether personnel, order or material data-with just a few clicks of a mouse, this component of APplus gives you the actual status of your company processes.

APplus plant data collection offers you

- Staff time recording

- Personalmanagement

- Mobile staff time recording

- Order time recording

- Machine Data Acquisition

- Electronic leave requests

- Access control

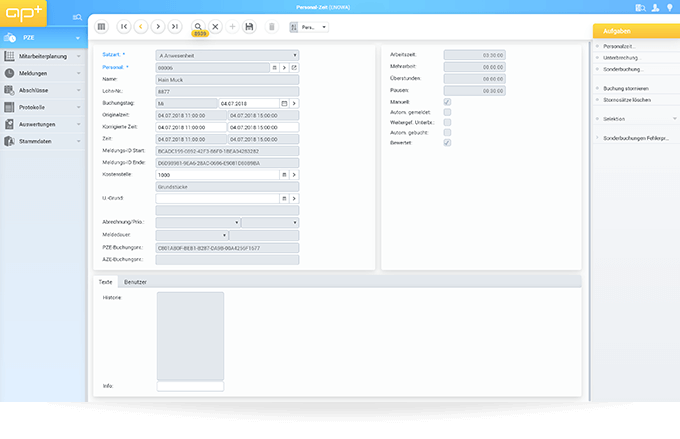

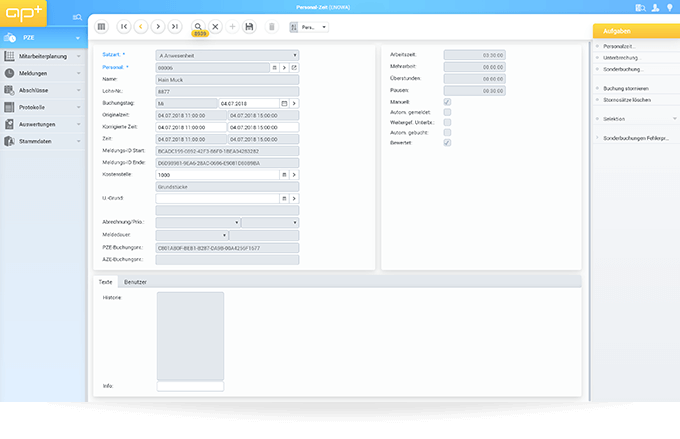

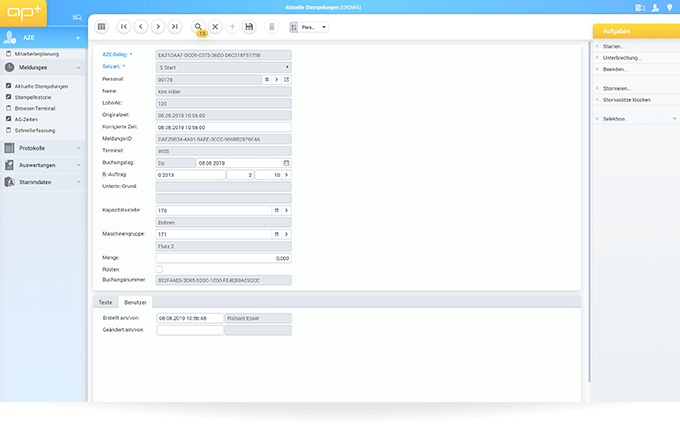

Personnel time recording

In the area of personnel time recording, APplus meets even stringent requirements profiles, giving you the ability to define flexible time, shift and accounting models. Overtime management with annual work time accounts, leave management, and access control provide support for a modern system of presence time management.

High-quality industrial terminals are used as devices for recording data. Alternatively, a computer-based input screen is used, which, due to its online Internet capability, also permits the collection of decentralized time reporting at subsidiaries or even for service calls or site installations.

Both wage accounting and production control benefit significantly from APplus PDC. Fully integrated into PDC, these components provide the advantages of minimal administration and access to up-to-date information.

Personalmanagement

In zahlreichen Unternehmen findet man die Personalakten noch immer in Papierform im Schrank vor. Das längst so wichtige Bewerbermanagement funktioniert über Wiedervorlagen und Excel. Durch den Einsatz von APplus Personalwesen können Personalprozesse jedoch wesentlich effizienter gestaltet und Ressourcen eingespart werden.

Die APplus-Software verknüpft nahtlos Personalverfügbarkeit und Kapazitätsplanung und unterstützt das Personalmanagement dabei, ein ganzheitliches Personalinformationssystem aufzubauen. Die Personalplanung kann so sicherstellen, dass genug personelle Ressourcen vorhanden sind, um die betrieblichen Funktionen zu erfüllen. APplus ermöglicht alle Mitarbeiterdaten an einem zentralen Ort zu verwalten und liefert Informationen und Daten in Echtzeit.

Mobile staff time recording

- Book times for

- Coming

- Leaving

- Interruptions

- Displaying the balance information from the ERP

- To make applications for leave

Order time recording

As soon as an order has been created in the PPS module and the corresponding workshop order papers (including barcode) have been generated, messages can be stamped on the order. Once times have been reported back, they are immediately available in the order or project progress tracking.

Thanks to the integrated handling of PPS and PDA information, collective orders and messages can be settled particularly conveniently. This benefits companies that have to produce a large quantity of individual parts with comparatively short cycle times.

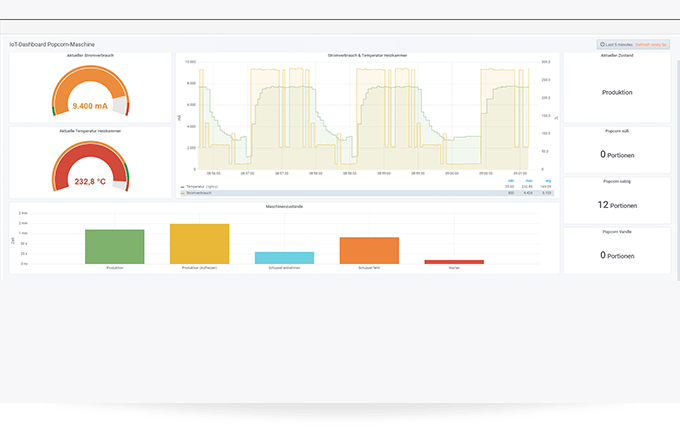

Machine data collection

On the shop floor, the task is to coordinate the large number of parallel customer orders. In addition, a complex machine park must be kept in view. At the same time, quality must be ensured at all times.

By recording machine data, relevant data such as production times, quantities and, if necessary, the duration of interruptions can be recorded objectively and in real time. This is already done in the simplest form through status signals such as "part finished" and "machine produced" or also interruption states. In addition, other machine information such as power consumption, speeds or potentiometer positions can be registered in parallel to the currently processed operation.

This machine data can be collected in a variety of ways: among others, directly from the control system (e.g. by reading data blocks from an S7 control system), by communicating with an existing OPC UA server or via IoT modules. The latter method in particular is a simple, low-cost approach to acquire data even from older machines (retrofitting) or - if this is not possible - to make control signals available in a simple way.

Particularly when a lot of machine data is available, further analysis options are available, e.g. via AI, in order to be able to make better quality statements or to realise scenarios for predictive maintenance.

Die in APplus integrierte BDE-Lösung ermöglicht die direkte Anbindung von Maschinen (MDE). Dadurch werden Betriebs- und Maschinendaten in Echtzeit erfasst, was eine vorausschauende Ressourcenplanung ermöglicht. Dies steigert die Wirtschaftlichkeit und Termintreue.

Die Order time recording bietet zusätzliche Vorteile. Sie ermöglicht die Überwachung des Auftragsfortschritts, die genaue Planung von Arbeitsabläufen und die präzise Kalkulation der Kosten.

Die mittlaufende Kalkulation erlaubt eine regelmäßige Überprüfung der aktuellen Kosten während des Auftrags, während die Nachkalkulation eine umfassende Analyse der tatsächlichen Kosten nach Abschluss ermöglicht. Beide Ansätze helfen, Abweichungen zu erkennen und zukünftige Planungen zu optimieren.

Durch die Kombination von Auftragszeiterfassung und Kalkulation erhalten Sie eine bessere Kontrolle über Ihre Produktion, verbesserte Ressourcenplanung, höhere Wirtschaftlichkeit und Termintreue.